Smart Factory Assembly by Bossard

Bossard's Smart Factory Assembly is an innovative solution for digitalising and automating the assembly line. The result is higher quality, increased traceability and more flexibility. On this page, you can get an overview of the different elements we offer as part of a customised solution that solves the challenges you face in your production environment.

Core elements of the digital assembly line

Digital and interactive work instructions

Digital and interactive work instructions

Digital and interactive work instructions are the foundation of the digital assembly line. With digital work instructions, the employee is guided through each step of the assembly process, and the benefits are many, including a faster onboarding and start-up of assembly processes, increased process reliability, quick and efficient crossover between assembly processes, etc. Learn more about the possibilities and benefits here:

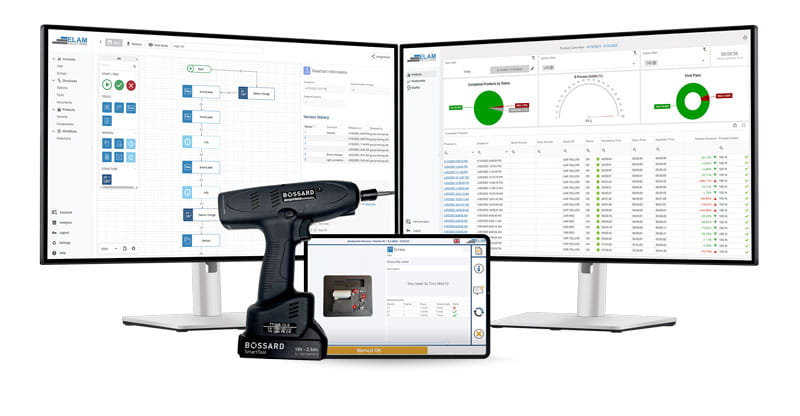

Smart tools og digital devices

Smart tools og digital devices

Connecting smart tools and digital measuring instruments and devices to the digital assembly line can automate processes such as tool and device changeover along with process data recording. This can simplify assembly processes and increase productivity. Read more about the multitude of devices that can be connected and the benefits you will enjoy here:

Data collection and process optimisation

Data collection and process optimisation

One of the most powerful tools the digital assembly line offers is the ability to collect and analyse real-time data about every step on the path to the finished product. With this knowledge, you have the possibility to optimise assembly processes and streamline production in order to minimise waste and maximise productivity. Read more about the possibilities here:

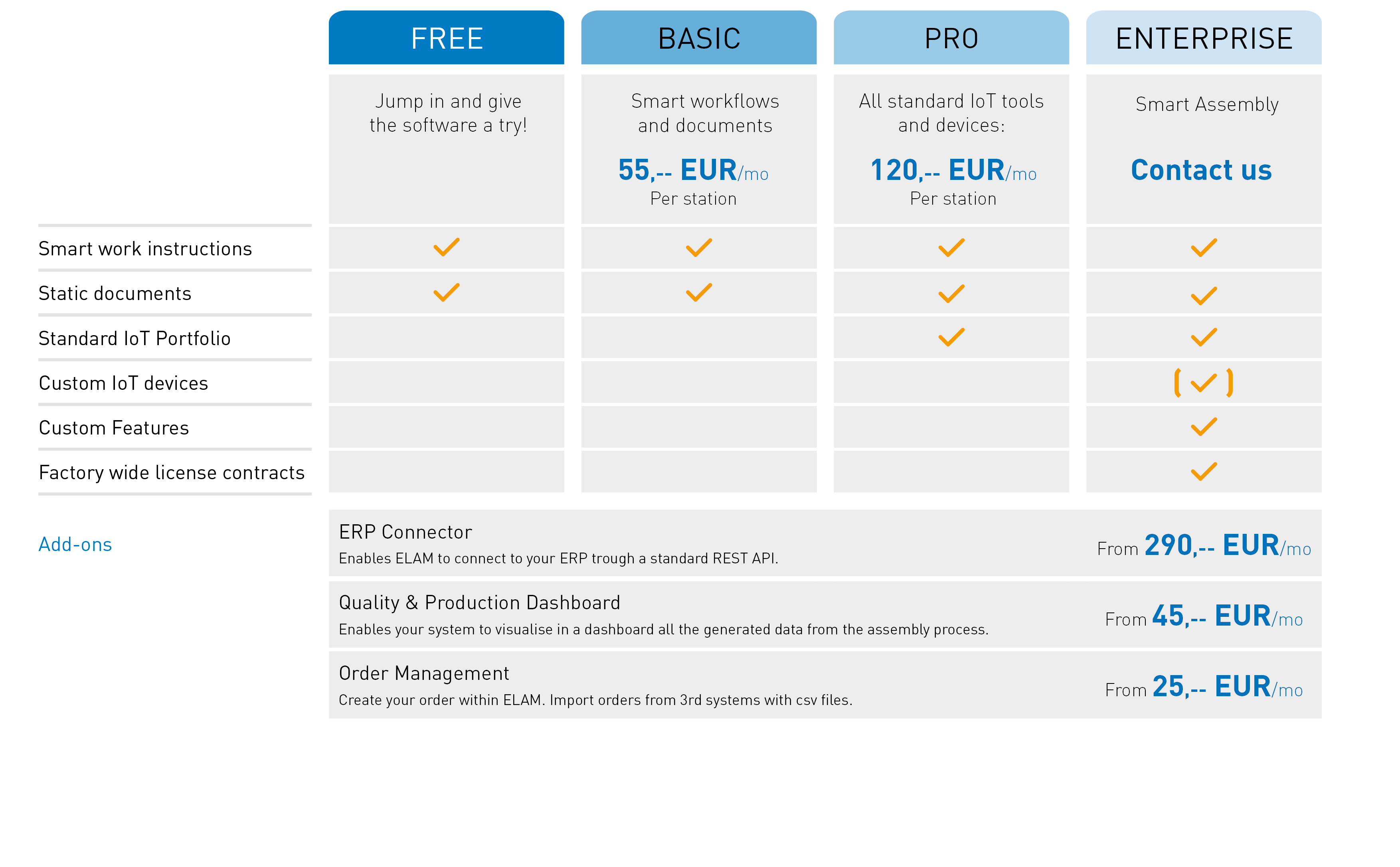

Our system is modular and scaleable

Quality data base

Smart work instructions

Static documents

Bossard Smart Tools

Standard IoT portfolio

Custom IoT devices

Production operation dashboards

Automated work instructions

ERP / MES integration

Software customisation

Free

Free software trial

✓

✓

✓

-

-

-

✓

-

-

-

Basic

Smart fastening and documents

✓

✓

(✓)

(✓)

-

-

✓

-

-

-

Pro

All standard IOT tools and devices

✓

✓

✓

✓

✓

-

✓

-

-

-

Enterprise

Smart Assembly

✓

✓

✓

✓

✓

(✓)

✓

✓

✓

(✓)

Why invest in the digital assembly line?

As a supplier to over 2,000 companies in Scandinavia, we have seen how the most competitive manufacturing companies are also the ones that actively include digital solutions in their production. This is because, among other things, these companies are able to minimise resource waste while increasing their adaptability and productivity. And that's exactly what Smart Factory Assembly can do. We basically make your tools and components talk to you and give you information, so you can identify inefficiencies and errors in your production and take action in time to improve exactly where it's needed. In this way, you avoid slowing down your growth, keeping your production resilient in both up and down times.

As a supplier to over 2,000 companies in Scandinavia, we have seen how the most competitive manufacturing companies are also the ones that actively include digital solutions in their production. This is because, among other things, these companies are able to minimise resource waste while increasing their adaptability and productivity. And that's exactly what Smart Factory Assembly can do. We basically make your tools and components talk to you and give you information, so you can identify inefficiencies and errors in your production and take action in time to improve exactly where it's needed. In this way, you avoid slowing down your growth, keeping your production resilient in both up and down times.

- Vincent Christensen, Business and Market Developer for SFA

Digital and interactive work instructions

One of the core elements of Smart Factory Assembly is the digitisation of work instructions, a solution that makes the assembly process more efficient and safe.

With digital work instructions, the operator is guided through each step of the assembly process. This offers several benefits. Onboarding of new employees is significantly faster. And employees can be confident that they are performing the correct processes and avoiding mistakes, even when switching from one assembly process to another. New work instructions and updates are implemented centrally and digitally, eliminating the need to keep track of different paper versions. Learn more here.

Display options

Touch screen

Tablet

Projector

Smart glasses

The digital work instructions can be displayed in a number of different ways. Available display solutions include: tablet, screen, projector and smart glasses. Each display option has its advantages in relation to the workstation setup. For example, a tablet is a good solution for assembly processes where flexibility is needed. What all solutions have in common is that the employee can interact with the device. The operator has the option to indicate that a task is complete and move on to the next step in the assembly process, either by tapping on a touchscreen or using gestures that are detected by sensors. Employees also get information delivered directly to the display solution, such as information about errors in the assembly process. Learn more about the display options here.

Benefits

Quicker production start and onboarding

Quicker production start and onboarding

High proces reliability

High proces reliability

Quick changeovers between assembly processes

Quick changeovers between assembly processes

High efficiency and quality, even in smaller lots

High efficiency and quality, even in smaller lots

Central updating of work instructions

Central updating of work instructions

Download our brochure

Get a full overview of all the possibilities with Smart Factory Assembly. Download our brochure and get insights into all the features and benefits you will enjoy, as well as a step-by-step guide to get started with digitising your assembly line.

Smart tools and digitally connected devices

Manufacturing companies use a lot of invisible resources on setting, calibrating and configuring tools. But it's possible to simplify this process significantly. With Smart Factory Assembly, we offer a simple solution to connect and integrate smart tools and devices on the assembly line. This solution increases productivity and process reliability and can be customised to specific needs.

Which devices can be connected?

Screwdrivers and rivet tools

Pick-by-Light and tower systems

Scanners, cameras and sensors

Digitale measuring instruments

Cobots / robots

Most digital tools can be connected to the digital assembly line. Screwdrivers and rivet tools, scanners, sensors and digital measuring instruments such as scales and electrical test equipment are just some of the examples.

Not only do digital tools make it possible to properly calibrate the tools, they can also help ensure that operators perform the assembly correctly every time. Tools can be locked and unlocked depending on the stage of the assembly process and can provide feedback to the system, making it easy to detect errors early in the process.

It is also possible to connect devices that further increase productivity, such as Pick-by-light, which makes it possible to quickly and easily find the next component from the right storage box, and Cobots / robotic arms that can perform parts of the assembly and support the operator's work.

Read more about the digital devices here.

Benefits

Automatic tool setting and calibration

Automatic tool setting and calibration

Maximum process reliability

Maximum process reliability

Automate data collection

Automate data collection

Faster workstation setup

Faster workstation setup

Wide range of tool integrations

Wide range of tool integrations

Data analysis, quality control and process optimisation

Digitisation of production processes can have a significant impact on a company's efficiency and competitiveness. Companies can gain a number of benefits by actively utilising digital production and quality data. Collecting and analysing data generated during the production process can give companies a deeper insight into their work processes and identify areas where there is room for improvement.

What does digitising production data achieve?

One of the main benefits of recording production data is that it allows you to perform technical tests during assembly and both perform ongoing quality control and track progress in relation to production targets. This allows any problems or errors to be detected early in the process, which can save the company costly corrections later in the process.

Another benefit is the increased transparency of the production process, which allows for quick and simple analyses and the implementation of process improvements on an ongoing basis. Companies can use the data to identify inefficient processes and optimise their production to reduce costs and increase productivity.

Benefits

Data-driven optimisation of the production process

Data-driven optimisation of the production process

More efficient quality control process

More efficient quality control process

See progress in relation to production targets

See progress in relation to production targets

Complete product lifecycle tracking

Complete product lifecycle tracking

Perform technical tests during assembly

Perform technical tests during assembly

Want to learn more? We would be happy to go through the opportunities offered by Smart Factory Assembly in your context.

We can create a case study for your company and organise a live demo of our systems, either online or on site at one of our customers who have already implemented Smart Factory Assembly in their production.

Use our contact form or call us directly.

Bossard Denmark A/S

Stamholmen 150

DK-2650 Hvidovre